0086 0755 21380136

0086 0755 21380136

0086 0755 21380136

0086 0755 21380136

sales@megarevo.com.cn

sales@megarevo.com.cn

2024-11-22

2024-11-22

Industry information

Industry information

Megarevo

Megarevo

Summary: When selecting the input mode for an inverter, different coupling methods process electrical signals differently. The generated signals can be broadly classified as AC (Alternating Current) and DC (Direct Current). Coupling is a way for an inverter to connect electrical energy.

In recent years, photovoltaic (PV) power generation technology has developed rapidly, but power generation is unstable. Direct large-scale grid connection will affect grid operation. With the addition of energy storage devices, power output becomes stable, allowing safe power transmission to the grid. There are many technical routes currently, but energy needs to be aggregated at a certain point. Currently, there are two main topologies structures: DC Coupling and AC Coupling.

I. AC Coupling

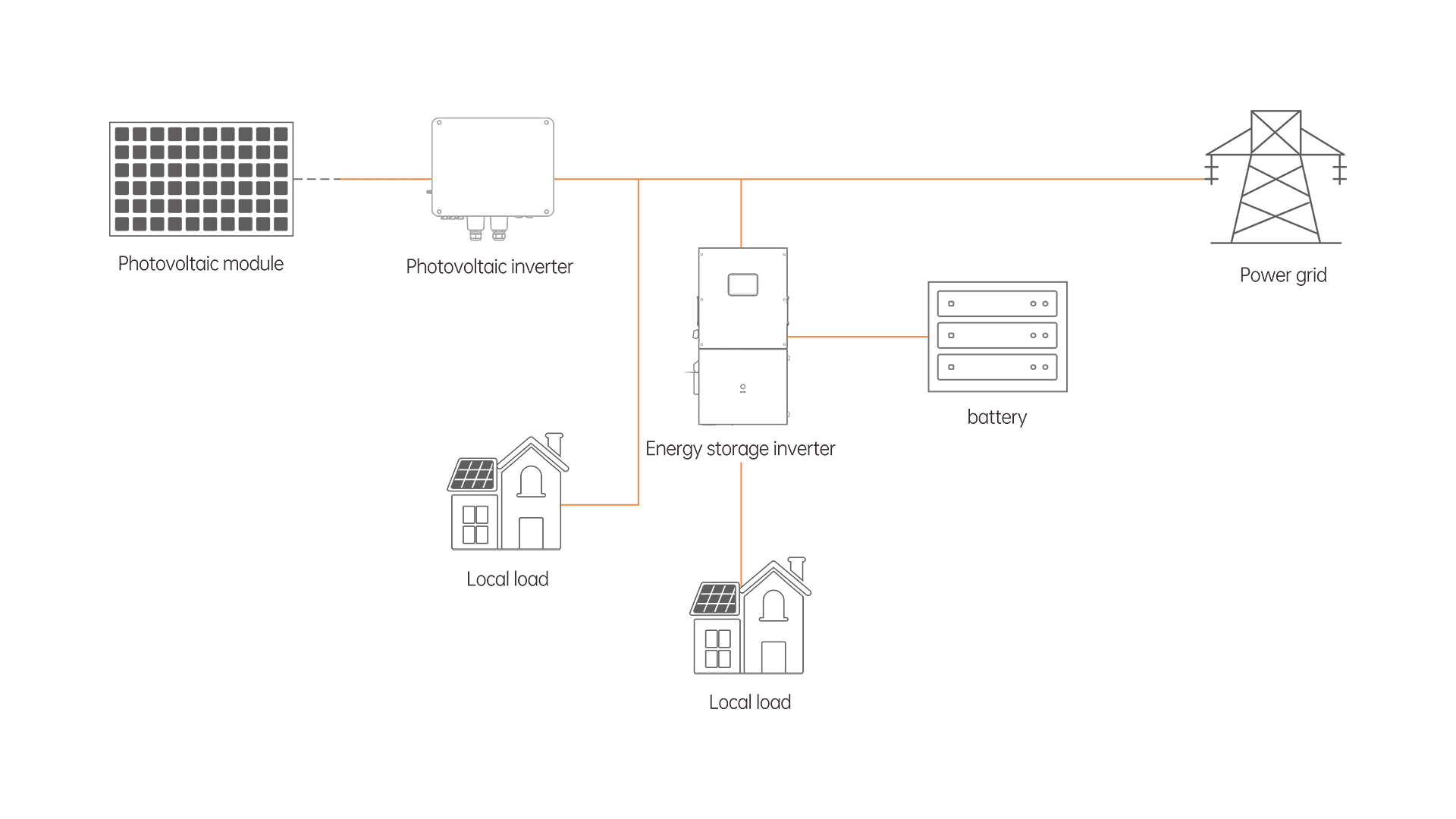

AC coupling is a common layout scheme. Energy storage and solar power generation systems operate independently and are coupled on the grid side. The advantage of this layout is that the two systems can operate independently without interfering with each other, making it easy for operational management and grid dispatch. It offers flexible connections and makes it more convenient to add or remove equipment.

This scheme can be applied to both existing and new PV markets. For example, adding a new energy storage system to an existing PV system can be directly integrated into the equipment without additional system design adjustments. AC coupling systems are suitable for situations where electricity consumption is high during the daytime, as they can directly supply power to loads through PV inverters.

II. DC Coupling

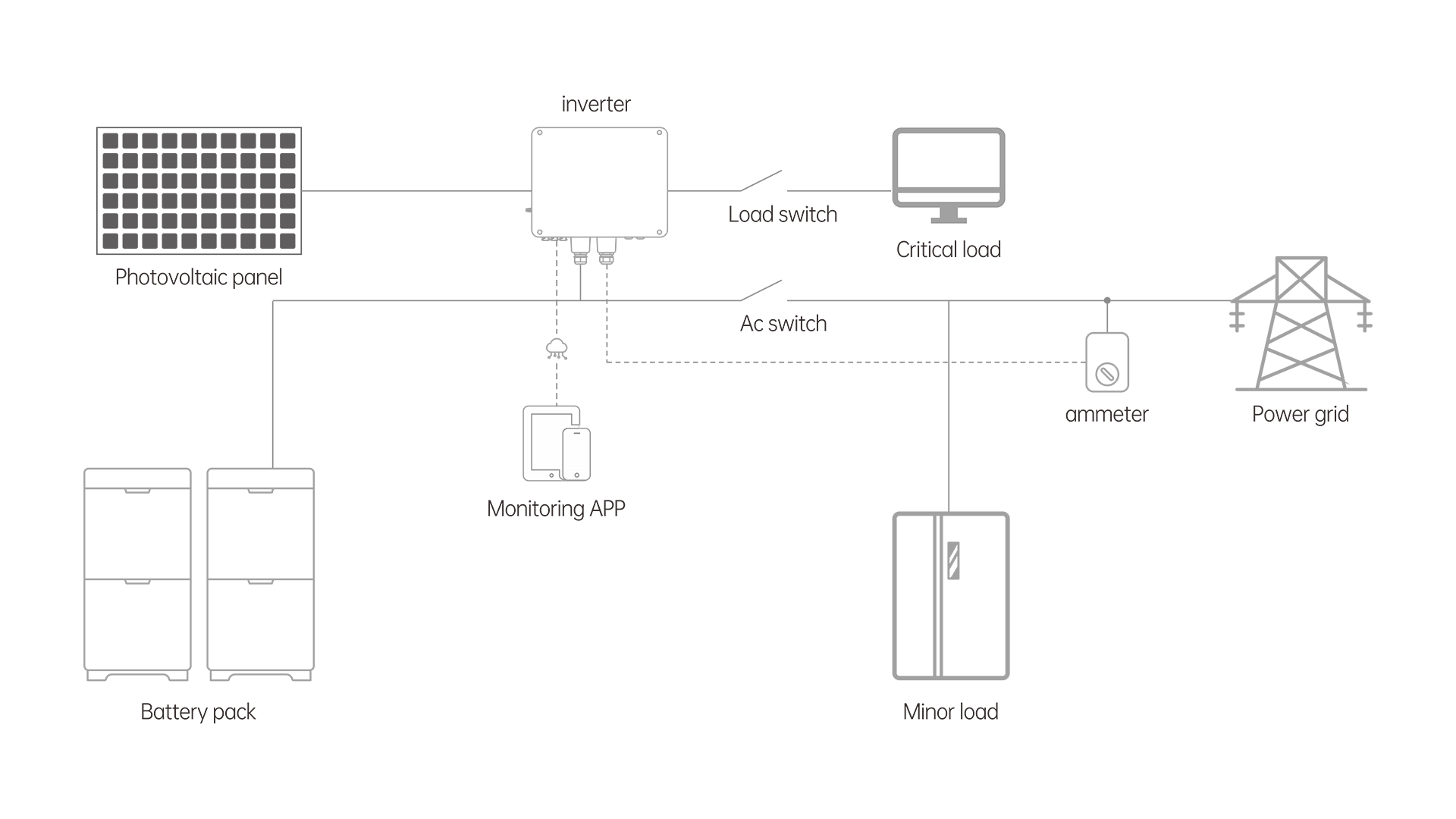

The common layout for DC coupling is where solar panels and energy storage batteries are directly connected to the inverter. This eliminates the need for energy storage equipment, significantly reducing the cost of the PV-storage system. This method is suitable for households that are just starting to use solar and energy storage equipment.

This scheme can transmit DC power generated by solar panels to the battery for storage or convert it into AC power for electrical appliances. However, because all devices are connected together, adding new equipment requires reinstalling the entire system from scratch.

III. Detailed Application Scenarios, Advantages, and Disadvantages

In the residential storage sector, DC coupling is more cost-effective because it uses fewer devices. AC coupling is more commonly used in existing markets, where households have already installed PV systems and wish to add energy storage systems. DC coupling is more commonly applied in incremental markets, where entire PV-storage systems are installed from scratch.

In terms of energy utilization efficiency, DC coupling outperforms AC coupling. In AC coupling systems, PV energy undergoes multiple conversions, resulting in significant energy losses, with an overall efficiency of about 90%. In contrast, DC coupling charges batteries through MPPT, with minimal energy loss and an overall efficiency of over 97%.

In terms of cost, DC coupling is also superior to AC coupling. One obvious point is that AC coupling requires two inverters, while DC coupling only needs one. Additionally, DC coupling offers energy storage all-in-one options, providing advantages in both equipment and installation costs.

In terms of system flexibility, AC coupling systems have an advantage. AC coupling systems have modules in parallel, making it extremely convenient to add or remove modules. In contrast, DC coupling system modules are tightly connected, making it relatively complex to add or remove modules.

It should be noted that in practical applications, the characteristics of DC coupling and AC coupling are not absolute. For example, in specific scenarios, AC coupling systems can also achieve efficient operation. Therefore, when selecting the system coupling method, it is necessary to comprehensively consider the actual situation and make the optimal decision.